Emerald Enhancements: A Consumer and Trade Guide

Regardless of origin, perhaps 99% of all cut emeralds are sold with some sort of enhancement for clarity. Since emeralds freshly dug out of the ground from any mine in the world are never found with naturally occurring oils or resins in them, all emerald clarity enhancements are considered artificial processes.

The 10.17-ct Shakiso Dream Emerald from Ethiopia has no clarity enhancements. Photo © DANAT, courtesy of Jeffery Bergman.

Table of Contents:

- Why Do Emeralds Receive Enhancements?

- Treatment or Enhancement?

- What Substances are Used for Emerald Enhancements?

- Can Other Types of Enhancements Improve Emerald Color or Clarity?

- Types of Clarity Enhancing Substances

- Soft Fillers

- Surface-Hardened Fillers

- Hard Fillers

- Natural Fillers

- Notes on Cedarwood

- Synthetic Fillers

- Mixing Oils and Resins

- The Filler Fights

- Can Resin Hold an Emerald Together?

- How an Epoxy Resin Became “Palm Oil”

- A Voice of Reason

- Hardened vs Unhardened Resins

- Gematrat/ExCel

- PermaSafe

- Liquid Oil vs Liquid Resin Stability

- GIA Testing Results

- Reality Check

- What’s the Most Effective Emerald Enhancement Technique?

- Clarity Enhancement Procedure

- Comparing the Effectiveness of Various Oils and/or Resins

- What COULD be in an Emerald?

- Contamination from Cutting

- Contamination from Cleaning

- Mixed Residues of Old and New Fillers

- No Fillable Fissures vs No Enhancement

- The Emerald Report Shell Game

- Advanced Deceptions

- Fighting Back

- How to Detect Emerald Enhancements

- Microscope

- Interference Colors

- Bubbles

- Dendritic Pattern Inclusions

- Hot Point

- FTIR

- Ultraviolet Light

- Confocal Raman Microscopy

- Microscope

- Quantification of Clarity Enhancement

- Clarity Enhanced vs Cavity Filled and Composite Emeralds

- Residue After Polishing

- Residue After Cleaning

- Emerald Enhancements and Pricing

- Pricing for Unenhanced Emeralds

- Conclusion

- Consumer Advice

- Trade Advice

- Gemological Laboratory Disclosure Notes for Emerald Enhancements

- AIGS (Asian Institute of Gemological Sciences)

- AGL (American Gemological Laboratories)

- Bellerophon GemLab

- CDTEC (Center of Technological Development of the Colombian Emerald)

- DANAT (Bahrain Institute for Pearls and Gemstones)

- GIA (Gemological Institute of America)

- GIT (The Gem and Jewelry Institute of Thailand)

- GRS (Gem Research Swisslab)

- GTL (Gem Testing Laboratory, Jaipur)

- GTTL

- Gübelin Gem Lab

- Guild GemLab

- ICA GemLab (International Colored Gemstone Association)

- Lotus Gemology

- NGTC (National Gemstone Testing Center)

- SSEF (Swiss Foundation for the Research of Gemstones)

- Stone Group Laboratories

- Acknowledgements

- References and Further Reading on Emerald Enhancements

Why Do Emeralds Receive Enhancements?

Aquamarine and emerald are both members of the beryl family, and while exceptionally large and clean aquamarine crystals are relatively common, emeralds grow in geological conditions which only very rarely produce clean crystals. Natural inclusions common to emeralds from any location are affectionately referred to as a jardin, which means “garden” in French. An emerald’s jardin often includes surface-reaching fissures that virtually disappear when filled with transparent liquids.

Typically included Colombian Emerald crystal. Photo © CDTEC.

Typically clean Aquamarine crystal. Photo © minfind.com.

Treatment or Enhancement?

Enhancing gemstones to improve their appearance is a time-honored tradition dating back over 3,000 years. Archeologists discovered heat-enhanced carnelian dated to about 1,300 BCE in Tutankhamun’s tomb. The writings of Pliny the Elder (1st century CE) discuss many gemstone enhancement techniques including foil backing, oiling, and dyeing. These techniques, applied to gemstones for over 2,000 years, are still popular today.

But what should we call these techniques?

Quoting industry experts Richard W. Hughes and Ray Zajicek from Catfights: Enhancement codes & trade wars (1997):

After much contemplation (RZ) and a look at the dictionary (RWH), we have come to the conclusion that enhancement is the best way of referring to the methods used for altering the appearance/stability of gems. In common English, treatment is a cure for sickness, while enhancement refers to improving quality. Seeing as how treatments are a fact of life in today’s gem market, we might as well put a positive spin on things. Thus the authors feel that the most appropriate term is enhancement.

What Substances are Used for Emerald Enhancements?

In The Oil Treatment of Emeralds in Bogota, Colombia (1983), emerald expert and author Ron Ringsrud wrote:

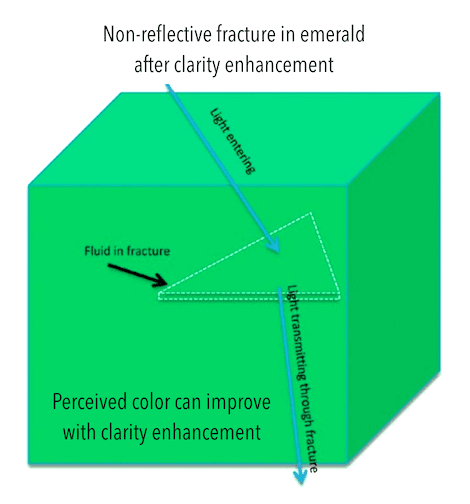

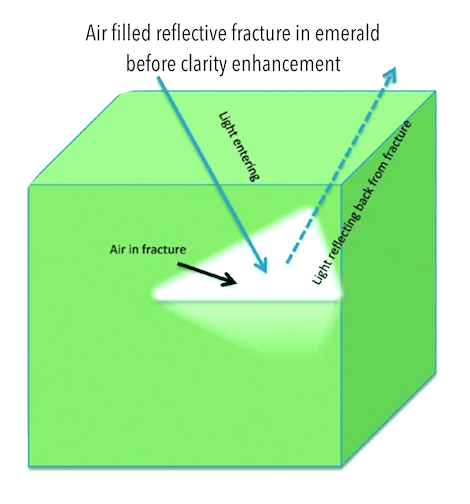

Records of actual oiling of gem crystals go back as far as ancient Greece…. The principle of oiling is simply that while air-filled fractures in gemstones are highly visible, a fracture filled with a transparent oil or some other suitable material will be much less apparent. While the oiling changes only the clarity characteristics of the gemstone, the color will naturally [appear to] be intensified because of the fewer apparent flaws blocking the passage of light.

Note: the change in color can’t be “natural” if it results from an enhancement process! (RWH)

Historically, jewelers have used various colorless or near colorless oils, waxes, and resins to improve the appearance of turquoise, jade, and emerald. These include liquid paraffin, mineral oil, clove oil, Canadian balsam, and cedarwood oil. More recently, jewelers have adopted a variety of synthetic liquids, such as epoxy resins and polymers, for gemstone enhancement.

When the enhancing liquid is strongly colored, the finished product is considered not only clarity enhanced but also dyed. Such is the case with green Joban oil, commonly applied to low-quality emeralds in Jaipur, India.

Indian Joban is a green dye in oil. Photo © Cecile Raley.

Green dye concentrated in emerald fractures. Photo © GraysOnline.

Can Other Types of Enhancements Improve Emerald Color or Clarity?

Heating doesn’t improve the color or clarity of emeralds.

Irradiation can alter the color of certain emeralds with an appropriate iron-chromium-vanadium ratio, but the vast majority of stones will see no improvement.

Laser drilling to open a surface-reaching channel to inclusions, then removing them with strong acids, is a well-known process for diamond clarity enhancement. However, the heat sensitivity of emeralds makes this process impractical, although it’s possible using a cold (non-thermal) ablation excimer laser. So far, laser drilling, dissolving of inclusions, and then filling with a transparent liquid is a virtually unknown practice with emeralds.

Types of Clarity Enhancing Substances

Soft Fillers

Epon® 828 and Araldite® 6010 (both sometimes misleadingly called “Palma”), cedarwood oil, unhardened Opticon®, paraffin oil, and Canada balsam.

Surface-Hardened Fillers

Norland Optical Adhesive 65, a longwave UV–setting adhesive, and Opticon Resin No. 224.

Hard Fillers

Gematrat®/ExCel® and PermaSafe®.

Natural Fillers

Cedarwood oil, Canada balsam, mineral oil, paraffin oil, beeswax, paraffin wax, cinnamon oil, clove oil, palm oil, castor oil, coconut oil, and oleoresins.

Notes on Cedarwood

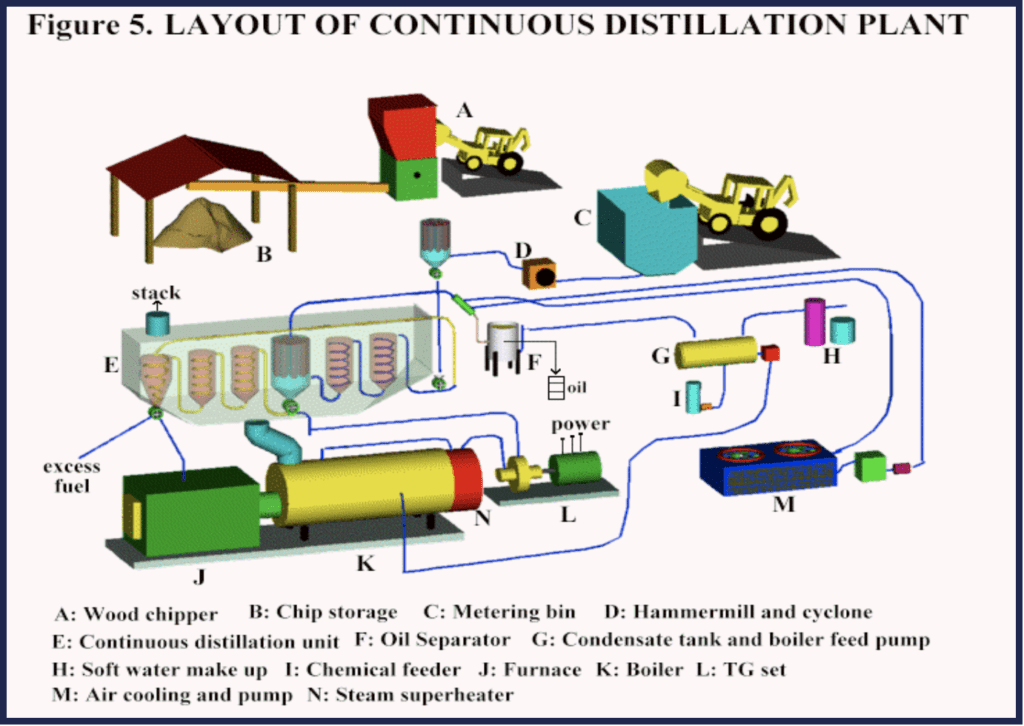

Since cedarwood oil is extracted from trees, it’s considered “natural.” However, the process isn’t as simple as hammering a tap into a maple tree, collecting the sap, and evaporating away the excess water content to make natural maple syrup.

Producing concentrated oil from cedarwood is a highly industrialized process. It involves harvesting the trees, chopping them into fine particles, forcing high-temperature and high-pressure steam/solvent through the wood particles, then fractionally distilling the extracted substance. So, cedarwood oil is natural in the same sense that diesel fuel, kerosene, or gasoline are natural.

There are three types of cedarwood oil:

- Low-viscosity: commonly used for wood treatment.

- Medium-viscosity: commonly used for aromatherapy, massage, and perfumes.

- High-viscosity (scientific grade): commonly used in research as an immersion oil for high resolution (1000X) light microscopy work and for emerald enhancements.

Synthetic Fillers

Epon 828 and Araldite GY 6010 prepolymer resin, EPO-TEK® 314, Opticon Resin No. 224, PermaSafe, Arthur Groom Gematrat, ExCel, HXTAL NYL-1®, NOA 65®, ThreeBond TB3074 high-transparency UV-curing resin, various epoxies and polyurethanes, plus a wide variety of acrylated epoxies, polyesters, acrylated urethanes, and acrylated silicones.

Mixing Oils and Resins

Blending natural and synthetic fillers is occasionally employed with varying results. Gemologists in Bogota, Colombia report the use of Ten-Noventa, which translates to “10-90,” meaning 10% cedarwood oil mixed with 90% synthetic resin.

The Filler Fights

Since the 1960s, gemstone hobbyists have relied on Opticon Resin No. 224 fracture sealer to improve the appearance of fractured mineral specimens and cut gemstones, especially cracked and/or crazed opals. Opticon can be applied with or without using a surface hardener and also can be completely removed with the solvent methylene chloride. With the brand name “Attack,” this solvent will dissolve cured epoxies and polyester resins.

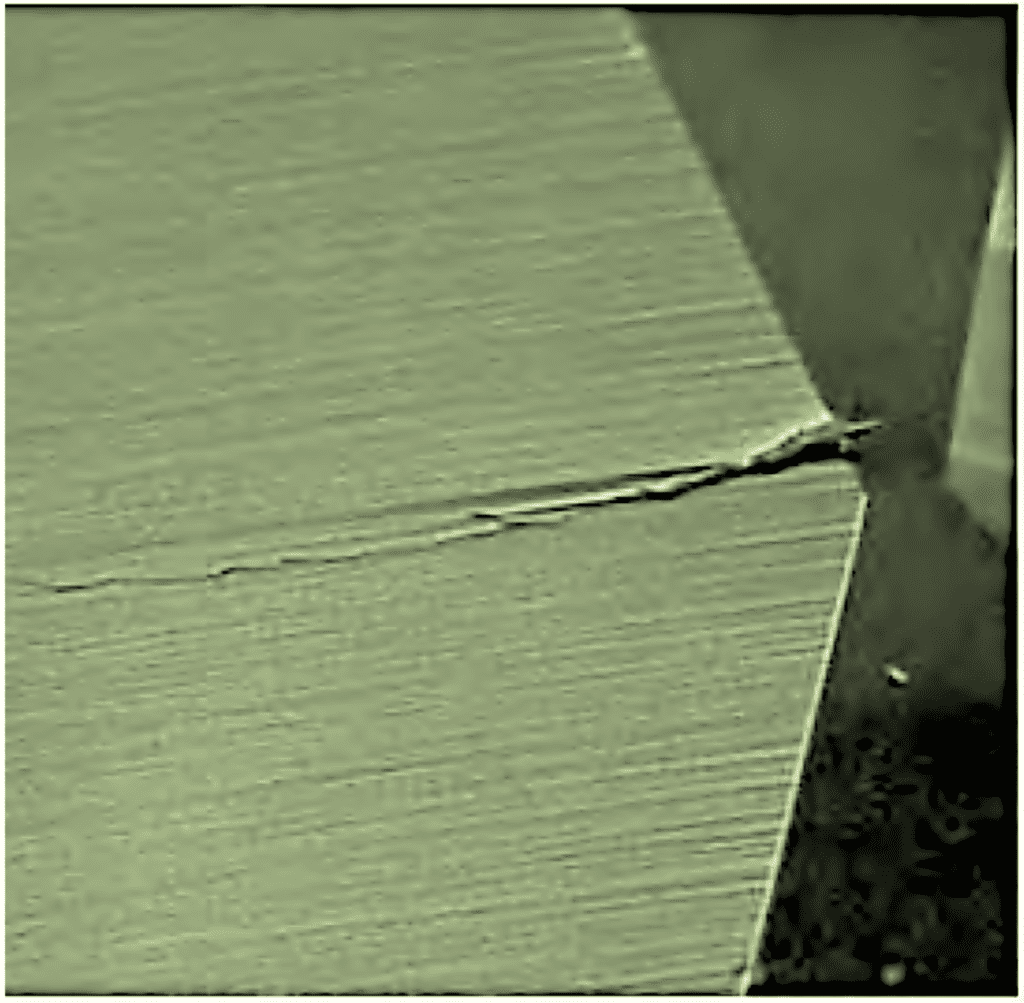

Can Resin Hold an Emerald Together?

Emerald cutters discovered that treating rough with Opticon greatly increased their rough-to-cut yield, sometimes as much as double. When cut from this rough, a finished emerald could have a resin-filled fracture potentially encircling it entirely. So, essentially, the emerald stone could be two pieces held together by the resin. Wholesale buyers eventually discovered this practice, resulting in considerable backlash. The perception — only very, very rarely justified — was that the enhanced emeralds would fall apart if the resin were removed.

How an Epoxy Resin Became “Palm Oil”

In the early 1980s, the Shell Chemical Co. developed a multitude of new, liquid-epoxy resins for a wide variety of industrial applications. For the vast majority of applications, epoxy resins are cross-linked by adding various reactive agents, an optional procedure commonly referred to as hardening or curing.

One of these new resins, No. 828, happened to have a refractive index (RI) of 1.573. Colombian emeralds have a RI of 1.57-1.58, while emeralds in general range from 1.565-1.59. (The favorite “traditional” clarity enhancer, cedarwood oil, has a RI of 1.51-1.52).

Colombian emerald enhancers discovered these new artificial resins. They became convinced the perceived clarity of their emeralds, after enhancement with Epoxy No. 828 (without the optional hardening procedure), was superior to those enhanced with cedarwood oil. Superior perceived clarity means a higher price per carat.

However, when consumers hear the term “epoxy,” they immediately associate it with glue. No one will buy an expensive emerald if they believe it’s held together with glue! So, the clever Colombian enhancers came up with a “solution” to the perception problem. They coined the trade name “Palma” for Epoxy No. 828. Promptly mistranslated as “palm oil,” the name misled many buyers into thinking it was a “natural” or “traditional” type of emerald enhancement.

A Voice of Reason

By the mid 1990s, several internationally prominent emerald dealers had published scathing essays and editorials on the evils of artificial resins. But the voice of one crying out in the wilderness — that is, SSEF Director Prof. Henry Hänni in Jewellery News Asia (June 1993) — poignantly suggested:

It is hypocritical to speak about the good old days when everyone used oil. For many years, the so-called oil used has often been a natural resin such as Canadian balsam or cedarwood oil. Natural resins were used because nothing better existed. (p.80)

Note: again, the word “natural” is a red herring. The entire process is artificial (RWH).

Hardened vs Unhardened Resins

Gematrat/ExCel

In 1995, Arthur Groom introduced Gematrat, an emerald clarity enhancement guaranteed for life that doesn’t change color or leak out of the stone. Capable of withstanding ultrasonic baths, steam cleaning, and the repolishing process without any changes to appearance, it’s also removable from its host stone, if necessary, without any adverse effect. In 1997, the lab added a UV fluorescent tracer to Gematrat to help gemologists identify the filler and determine how much was present in the stone.

The name was eventually changed to ExCel after it was improved by the product’s maker, Clarity Enhancement Laboratory (C.E.L.) in New York. The C.E.L. website boasts:

Due to the great stability of the ExCel process, retail and manufacturing jewelers can sell their emeralds with the confidence that their beauty and luster will give their owners a lifetime of enjoyment.

PermaSafe

Developed by the Centro Gemologico para la Investigación de la Esmeralda (CGIE) in Bogota, Colombia, PermaSafe is a permanent, synthetic, epoxy resin for emerald enhancements. This enhancement was intended to be a Colombian alternative to Gematrat/ExCel.

The tracer in ExCel was eventually eliminated, mainly due to the fact that labs in Colombia also added fluorescent tracers to their products. This lead to the confusion of ExCel with other fillers.

Liquid Oil vs Liquid Resin Stability

In Catfights: Enhancement codes & trade wars (originally published in the ICA Gazette, June, 1997), R.W. Hughes and Ray Zajicek observed:

As one can see, differences between Opticon and “traditional” oils are minor, except regarding evaporative stability. Opticon will not evaporate as readily as cedarwood oil. We cannot speak for others, but in our book, this is better. If we have to buy a fracture-filled emerald, let it be one in which the filling is stable.

At the 1st World Emerald Congress held in Bogota in 1998, Colombian delegates professed their willingness to use only cedarwood oil in the clarity enhancement of emeralds unless the customers requested another. Financial motivation trumped promises, and artificial epoxy resin-enhanced Colombian emeralds continued to permeate the market.

In early 2019, a prominent Bangkok dealer with decades of experience as an international trader in Colombian emeralds spoke with me on the condition of anonymity. He reported buying back stones he sold over 20 years ago, originally purchased in Bogota. These stones had received a clarity enhancement with 828 epoxy resin. The dealer mentioned that compared to emeralds enhanced with cedarwood oil, “Palma” resin-enhanced emeralds not only looked better but also demonstrated much greater long-term stability. (Personal communication).

Flying from Bogota to New York, Geneva or Bangkok subjects freshly enhanced emeralds to drastic temperature, humidity, and air pressure fluctuations. This accelerates the process of unhardened oils and/or resins leaking out of surface-reaching fractures. Due to this instability, emerald dealers commonly re-enhance their newly acquired emeralds upon arrival. This practice has resulted in several commercially manufactured multi-stage units on the market incorporating heat, vacuum, and pressure in order to refill oils or resins in an office setting.

GIA Testing Results

To conduct durability tests, GIA researchers enhanced 128 emeralds with a variety of fillers. In Durability Testing of Filled Emeralds (2007), M.L. Johnson reports:

None of the fillers used for this study were stable to all the tests, but the results imply that the best candidate with regard to the durability of the filled emerald’s appearance under conditions of normal wear and care appears to be a surface-hardened liquid.

To this day, an illogical snobbery still permeates the upper end of the emerald trade. The more stable resins are looked down upon, as they’re considered artificial or synthetic. On the other hand, cedarwood oil, with its inferior stability, is preferred because it’s considered natural.

Reality Check

Resins enhance the vast majority of emeralds on the market. Quoting emerald expert and ICA InColor Magazine Editor-in-Chief Jean Claude Michelou:

Consumer confidence is moving towards guarantees that the emerald’s initial appearance will not change with time. There are very, very few Colombian emeralds of significant size that can enter into “no oil” or “minor oil” categories. This is a very tiny part of the market and ever tinier part of the production. Appropriate resins used without any hardener seem to be much more stable since they mostly remain within the fissures. Respected labs, including Gübelin, GIA, AIGS, GRS, GIT, NGTC, Lotus and others, have aligned in not mentioning the type of filler, making no distinction on lab reports for oil or resin. (Personal communication)

With decades of experience in mining, cutting, and marketing Brazilian emeralds from the Belmont Emeralds mine in Brazil, company representative Rafael Colen commented:

Our primary concern is providing our customers with an emerald with superior long-term stability. It makes no sense to enhance a beautiful emerald with unstable cedarwood oil just because it is considered a natural product. Resins provide far greater long-term stability, which is of benefit to jewelers, and ultimately to consumers. (Personal communication)

What’s the Most Effective Emerald Enhancement Technique?

Since fissures reaching the surface of an emerald are filled with air, forcing a liquid oil or resin into these fissures with pressure alone will often trap air in the bottom of the fissure. After releasing the pressure, the trapped air bubble will gradually expand, pushing the liquid out of the fissure. Therefore, the most effective technique involves first removing the air from the fissures in a vacuum tank and then introducing the emeralds into the filler liquid while under vacuum. This ensures the liquid will penetrate to the deepest reaches of the fissures without trapping any air bubbles inside.

Illustration by Ken Scarratt, InColor, Dec. 2015 pg. 52. © ICA InColor.

At room temperatures, high-viscosity, scientific-grade cedarwood oil moves as slowly as refrigerated honey. Heating reduces the viscosity of the oil, which allows it to penetrate the deepest parts of surface-reaching fissures. A simple home slow cooker or crockpot will suffice for warming the cedarwood oil to an ideal temperature range of 80-90° C or 175-195° F.

Clarity Enhancement Procedure

The most effective procedure for optimum results seems to be a multi-step process:

- Heat the clarity-enhancing liquid to 80-90° C in a small, stainless-steel pressure cell.

- Place the hot pressure cell in a vacuum chamber with emeralds on a separate platform.

- Draw maximum vacuum to remove air from surface-reaching fissures in emeralds.

- Manually tilt the vacuum chamber to slide emeralds into the heated clarity-enhancing liquid.

- After bubbles stop rising from the heated clarity-enhancing liquid, slowly release the vacuum.

- Remove the pressure cell and pressurize to about 100 psi.

- After cooling to room temperature, release the pressure, remove the emeralds, and wipe clean.

Comparing the Effectiveness of Various Oils and/or Resins

R.W. Hughes examined the clarity enhancement of emeralds by fracture filling with various oils and/or resins with RIs of 1.500, 1.517, 1.531, 1.550 and 1.57. (Emerald’s RI ranges from 1.569 to 1.580). In The Digital Devil: Don’t Forget to Flush (2000), he reported that “between the various fillers, there is not a significant difference in appearance, at least to the naked eye.”

What COULD be in an Emerald?

Considered unacceptable in Colombia, applying a liberal coating of mineral oil, cooking oil, or even motor oil to gemstone rough is a common practice elsewhere in the world, since it often dramatically improves appearance. As discussed previously, rough might be processed with Opticon or other resins in order to boost cutting yield.

Contamination from Cutting

Sawing typically uses oil, or an oil-and-water mix, to lubricate and cool the slicing process. Faceting laps often use oils to distribute diamond grit or polishing compounds. Colombian cutters typically use wax to block surface-reaching fissures from contamination.

So, even before intentional clarity enhancement, surface-reaching fissures in a cut emerald might already contain several different foreign substances.

Contamination from Cleaning

Cleaning introduces yet another opportunity to complicate the situation. Acetone and various alcohols are common solvents for most oils and unhardened resins.

Although a thorough deep cleaning may remove all liquids, it can still leave behind minute, dried residues not dissolved by solvents. Typically milky or cloudy, these residues don’t enhance the clarity of emeralds, so most lab reports don’t routinely mention them.

As a cleaning solvent for emeralds, acetone is arguably the best. But, not just any acetone will do. The vast majority of nail polish removers are acetone-based. The more expensive ones contain a small percentage of lanolin (sheep fat) to reduce skin drying. When acetone-based nail polish remover with lanolin dries out, it leaves the sheep fat behind, coating the insides of surface-reaching fractures with yet another oil detectable by gem labs. When sheep fat mixes with cedarwood oil or resins, they quickly become cloudy and impair an emerald’s clarity. Therefore, use only 100% pure acetone for emerald cleaning. The same warning applies to over-the-counter alcohol-based cleaners and solvents.

Mixed Residues of Old and New Fillers

Next, intentional clarity enhancement can introduce a wide variety of oils, resins, and oil/resin mixes. A client down the line might prefer a specific filler, so a vendor may attempt to remove all previous foreign substances. Sometimes, the attempts are thorough. Sometimes, they aren’t. As a result, a new filler is introduced, but traces of the previous filler still remain deep within fissures.

The challenges of detecting mixed fillers have divided the gemological laboratories that issue reports into two camps: those that identify fillers and those that don’t.

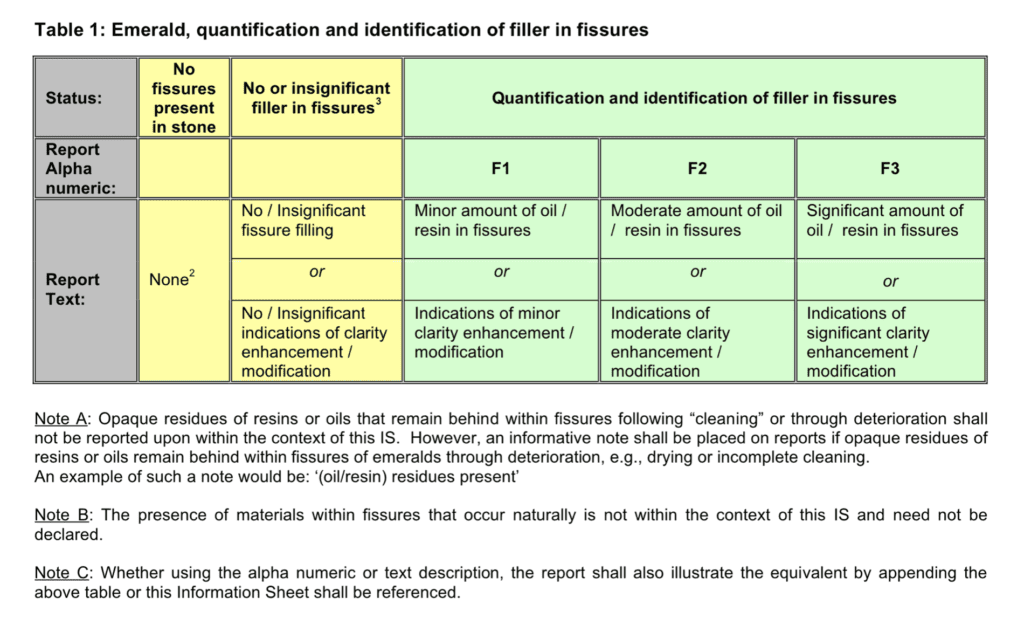

Laboratory Manual Harmonisation Committee (LMHC) standardized nomenclature describing emerald enhancements. Table © LMHC.

No Fillable Fissures vs No Enhancement

To paraphrase Shane F. McClure, Global Director, Colored Stone Services, GIA, who said it best at a GIA Gem Gathering in Bangkok on March 14, 2018:

There are emeralds which, although they show no evidence of clarity enhancement, could be, and probably should be, enhanced. Then, there are emeralds which cannot be enhanced.

The Emerald Report Shell Game

A very small number of unscrupulous dealers have been known to clean an emerald, obtain a “No Enhancement” report, refill the emerald with oil or resin, then sell it as a no-oil or no-resin stone for a premium price.

In Emeralds and the Saga of Cleaning and Filling Fissures(2018), SSEF Director Dr. M.S. Krzemnicki explains how this fraud works:

The scheme of such fraudulent use of gemmological reports (not necessarily only of SSEF reports) usually starts with an emerald containing artificial resin to hide its fissures. The stone is then thoroughly cleaned using chemicals until no filler is detectable anymore in the fissures. After this cleaning process, the emerald — now often showing prominent fissure features — is then submitted to a gem laboratory for testing, and eventually receives a testing report which indicates that no clarity modification was found.

To be attractive and saleable, the same emerald often urgently needs some clarity enhancement after the forced cleaning. Its fissures are therefore again filled with a colourless filler (commonly with oil). This is no problem as long as a new report is made stating the new treatment status of the emerald.

But it is also obvious from the above that selling an emerald which has been refilled but is still accompanied with the now outdated “no oil” report is fraudulent.

Due to this despicable trade-damaging practice, dealers and jewelers worldwide have adopted a protective safety mechanism. They will demand that a gem lab recheck the stone before making payment for “No Enhancement,” “Insignificant,” and sometimes even “Minor Enhanced” emeralds. Some buyers even require the lab to ship to them directly after the recheck in order to be 100% certain they’re receiving an emerald with a clean bill of health.

Advanced Deceptions

Unfortunately, what’s more difficult to detect is a partial cleaning to raise a “Moderate” to a “Minor” or “Insignificant” clarity enhancement grade, followed by refilling the removed oil or resin after a lab report is issued. This can make quite an effective deception. Buyers are less likely to recheck an emerald with a “Minor” or “Insignificant” grade than a “No Enhancement” grade.

Fighting Back

To address this disturbing practice, the SSEF introduced new wording in their reports:

Emeralds with no fillable surface-reaching fissures are described as follows: no indications of clarity modification at the time of testing.

Those emeralds containing fissures, but without any clarity modification by a fissure filler, are described as follows: no indications of clarity modification in fissures at the time of testing.

Those emeralds that do have fissures containing a filler substance for clarity modification are described as follows: indications of clarity modification; minor (or moderate, significant) amount of oil (or artificial resin, etc) in fissures at the time of testing.

These closing remarks by Dr. Krzemnicki in Emeralds and the Saga of Cleaning and Filling Fissures (2018) merit close attention:

Finally, we would like to remind our clients, that any comment on an SSEF report always indicates the opinion of the laboratory at the time of testing. We thus strongly recommend to first check the authenticity and validity of a SSEF report, and/or to have its current treatment status rechecked by SSEF, especially in case of emeralds with fissures, which may be filled so easily and fast.

As a result of these fraudulent practices, certain prominent gem labs have taken an additional precaution. They will no longer issue “No Enhancement” reports to specific dealers known to perpetrate this scam, unless the emerald has no surface-reaching fissures that could be filled after the report is issued.

How to Detect Emerald Enhancements

Microscope

Examining individual facets with a bright light reflecting off their surface will reveal surface-reaching fissures. If you can’t see a fissure below the hairline evidence on the surface, it’s a good indication the fracture is probably filled with a transparent substance.

Interference Colors

For microscopic examination, the rule of thumb is blue and/or yellow/orange flashes from internal fissures indicates clarity enhancement. However, naturally occurring rainbow-like interference colors — occasionally seen in unenhanced natural emeralds — have fooled more than one gemologist.

Naturally occuring interference colors in natural emeralds with no clarity enhancement. Photo © GTL Jaipur.

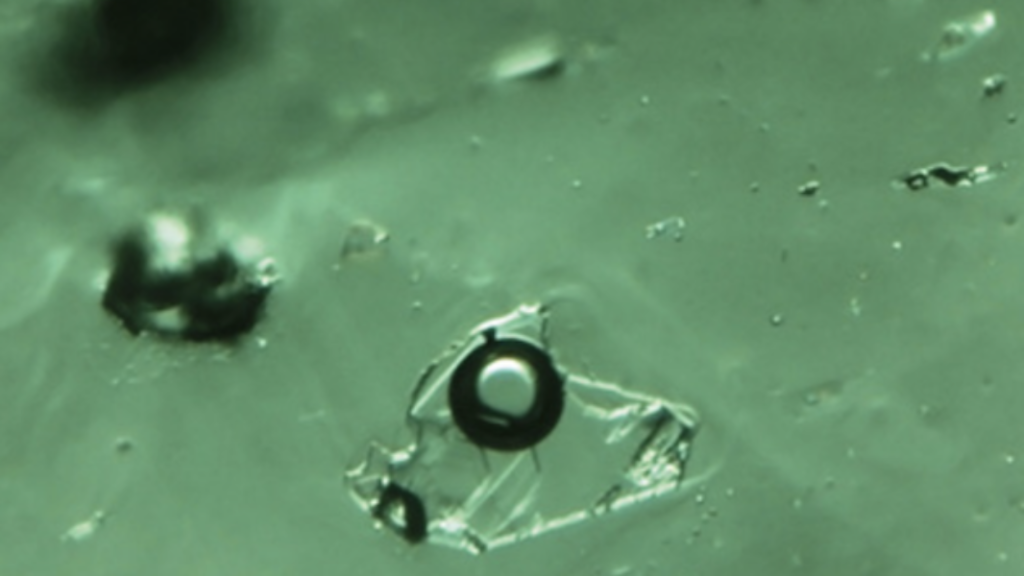

Bubbles

Inexperienced gemologists can also misinterpret bubbles as indications of clarity enhancement. Found in multi-phase inclusions, common to emeralds from many sources, bubbles require careful examination to separate gas bubbles in artificially introduced oils or resins from naturally occurring gas/fluid inclusions.

GIA gemologist Wim Vertriest reports witnessing naturally occurring gas bubbles expand and contract as a function of homogenization due to temperature change induced by the heat emitted from a microscope darkfield illumination light well. (Personal communication, 09-2019) Occasionally, inexperienced gemologists may misinterpret this observation as bubbles in oil or resin moving as they warm up.

Natural bubble in multi-phase inclusion. Photo © V. Pardieu.

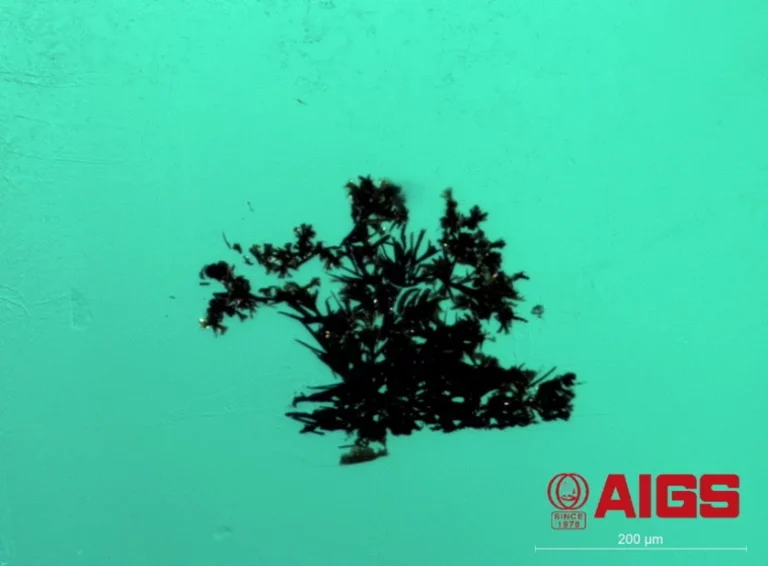

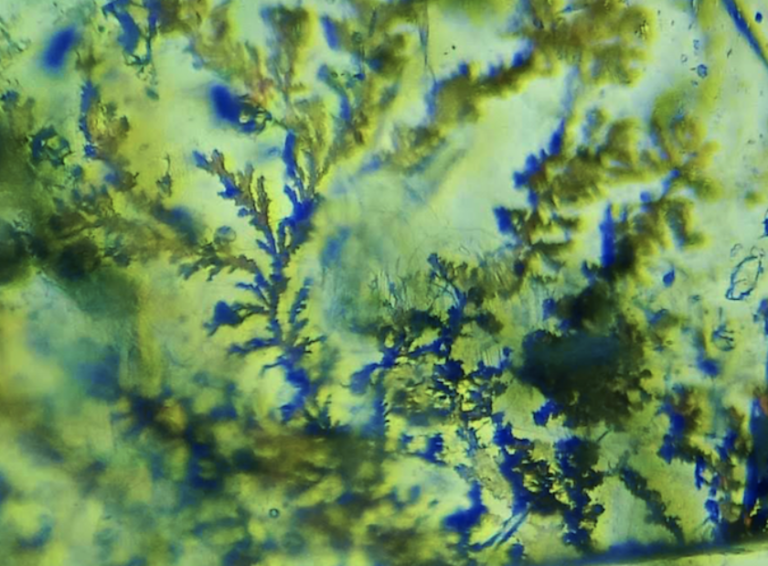

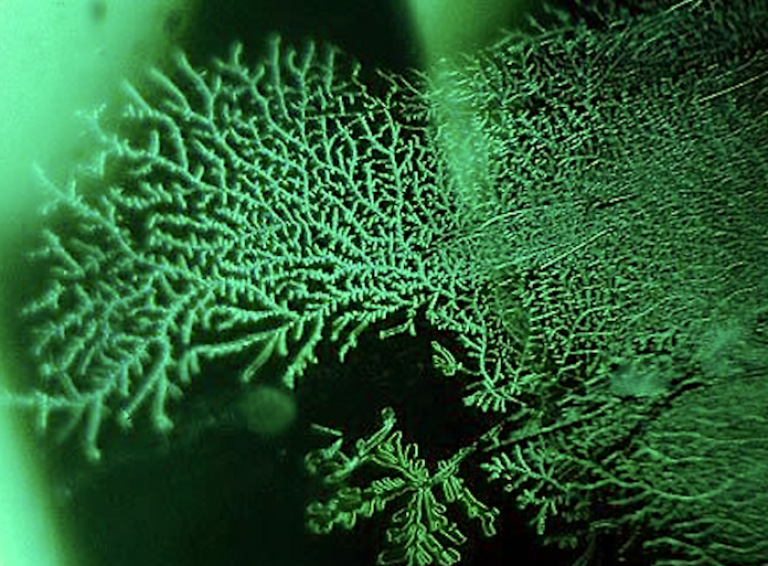

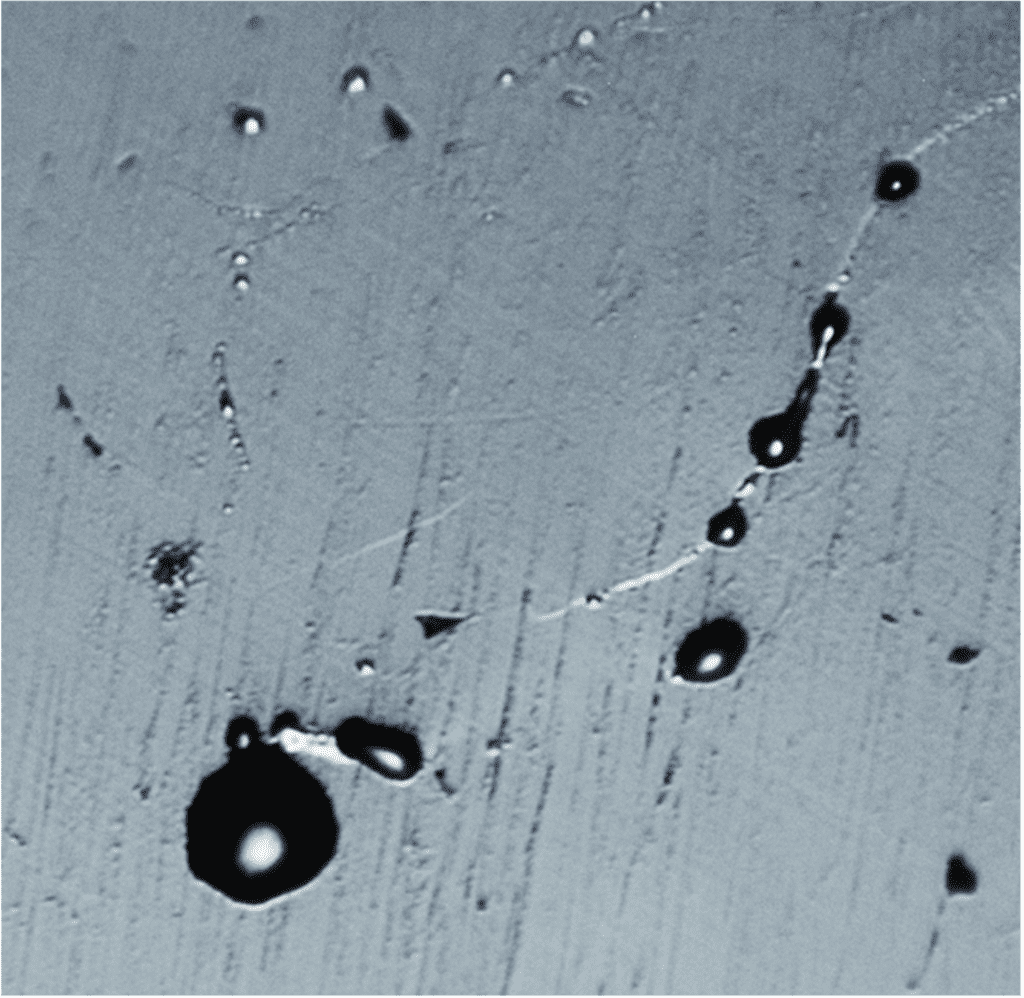

Dendritic Pattern Inclusions

Dendritic (“tree-like”) patterned inclusions are occasionally encountered in emeralds. They can occur naturally or as the result of dried clarity-enhancing liquids.

Natural dendrites are typically opaque black to translucent dark brown, while dendrites formed from dried clarity-enhancing liquids are transparent to translucent and colorless to slightly milky in appearance.

Make sure to examine dendritic inclusions in a variety of lighting conditions and from many angles. Since colorless and transparent dendrites can appear black, this can create the illusion they’re opaque. The only 100% conclusive method of determining the composition of these inclusions is confocal Raman microscopy.

Hot Point

Applying a hot point to a surface-reaching fissure under the microscope can often induce oils and/or unhardened resins to seep out. This is 100% positive proof of enhancement, more so than any other test.

For more information, read Lotus Gemology Lab Alert for Oiled Gems.

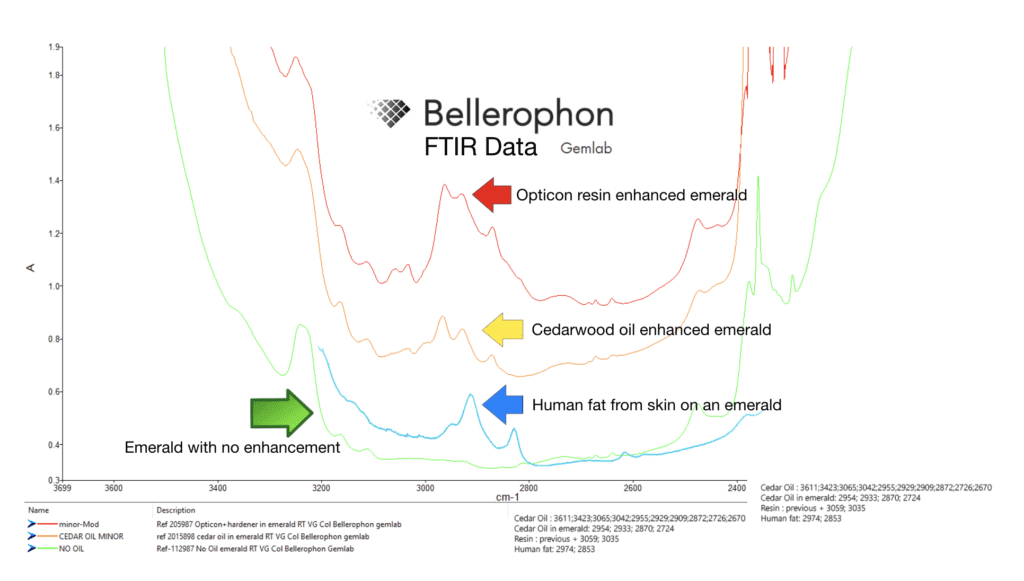

FTIR

Fourier transform infrared spectroscopy (FTIR) is one of the most important analytical technologies for detecting foreign substances in emeralds. However, it’s not foolproof. Occasionally, it won’t detect an “Insignificant” — and in rare cases “Minor” — enhancement in an emerald. In addition, it’s a “dumb” test. This means that while it can detect the presence of a substance, it can’t detect the amount. Thus, even an insignificant amount of a foreign substance can give a positive reaction.

Like any spectroscopic method, the strength of absorption peaks depends on the path length of the beam through the filler. If the beam moves parallel through a filled fissure, the absorption will be hundreds of times more than if it moves perpendicular to a fissure. (This is why, for example, the edge of a piece of “colorless” window glass looks green). The testing geometry also affects results. Many labs use only the beam condenser attachment and thus may miss important spectral features.

For more information on this subject, read FTIR in Gem Testing • FTIR Intrigue • Lotus Gemology.

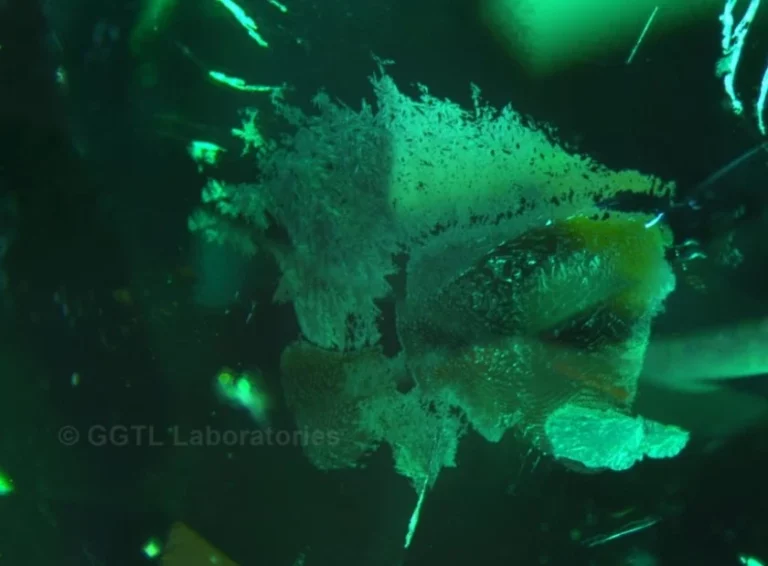

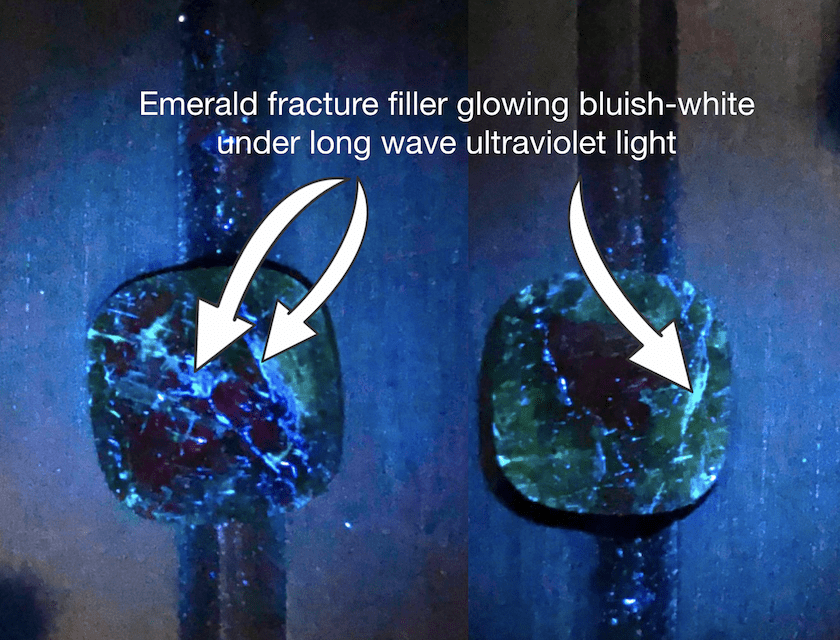

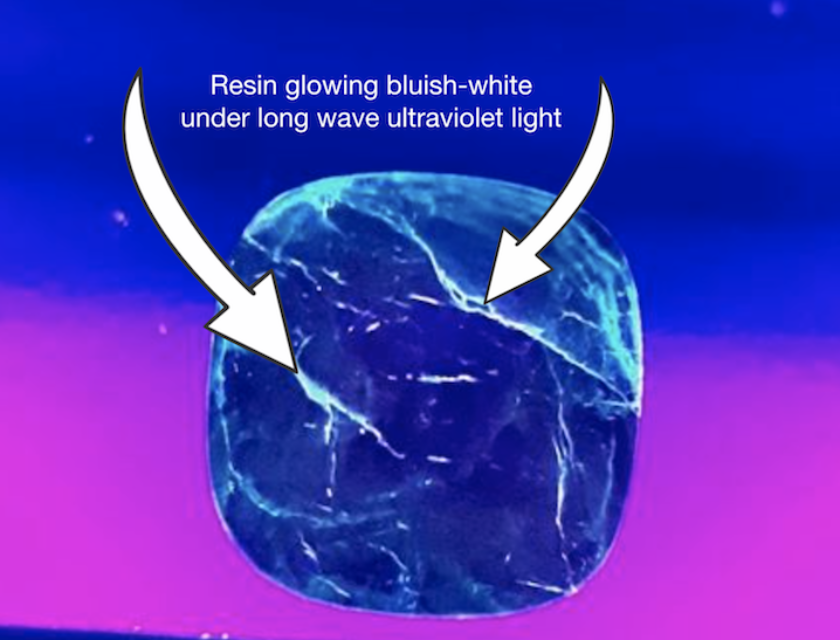

Ultraviolet Light

Isolating an emerald from other light sources and exposing it to longwave and shortwave ultraviolet (UV) light causes some oils and resins to glow white, light blue, light green, or light yellow. Therefore, UV light can be a valuable tool in detecting and quantifying emerald enhancements, except in the cases of rare inert substances. Using a fluorescence microscope or even a small magnifier allows you to detect this far better than with the naked eye.

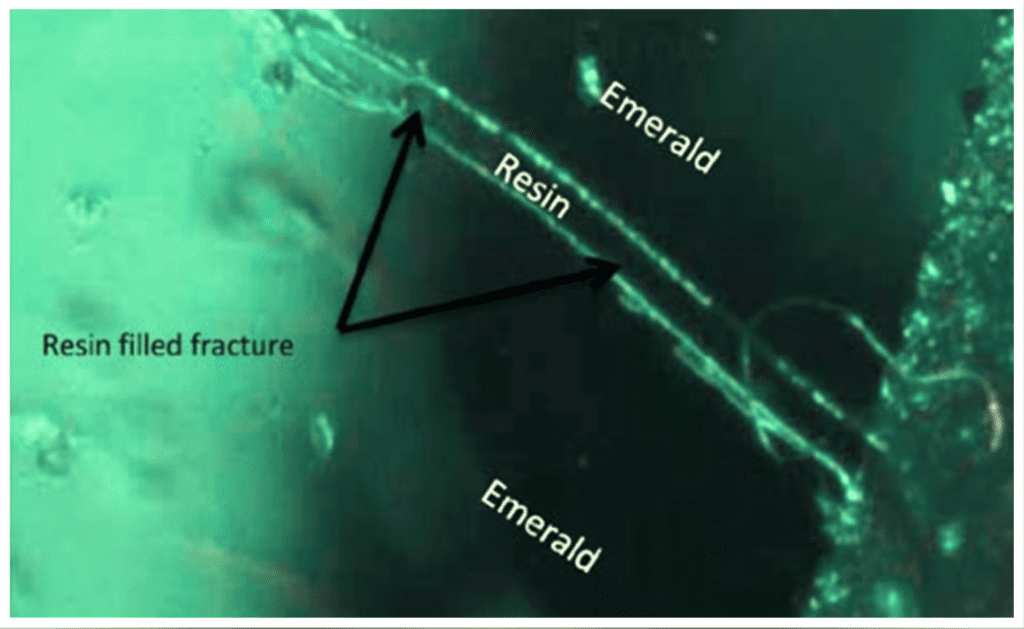

Bluish white glow reveals resin-filled fissures. © Bellerophon GemLab.

Confocal Raman Microscopy

The first and only reliable method to positively identify substances within fractures is the confocal Raman spectrometer, first utilized in the AIGS laboratory in Bangkok in 1993. Subsequently, every major gem lab in the world has adopted this technology.

Confocal Raman microscopy focuses a minute pinpoint of laser light on the filler in a fracture. The light scattered off the filler creates a spectrum that a computer can analyze and compare against a database, allowing specific identification of oils and resins.

This technique suffers from many of the same problems as FTIR, but when the hot point coaxes oil from a fissure, a researcher can analyze it with the Raman microscope. Obviously, mixed fillers will give mixed results.

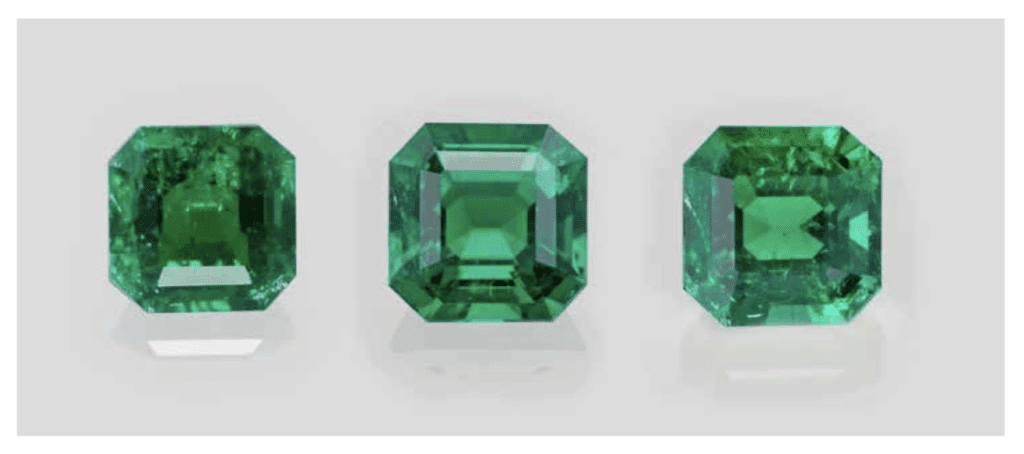

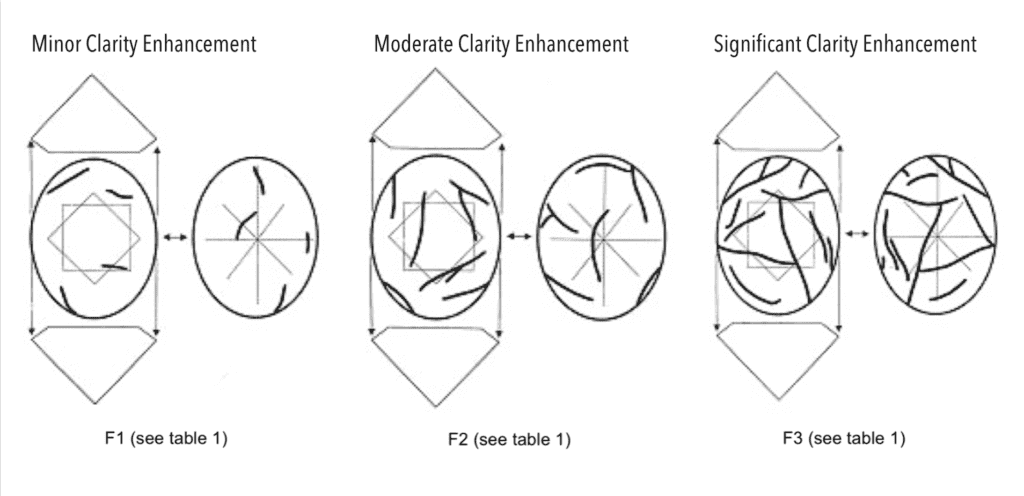

Quantification of Clarity Enhancement

A small percentage of emeralds have only one or two very small surface-reaching fissures. Others have many more and/or much larger individual fissures. Therefore, gem labs have developed a quantification system reflecting the number, size, and position of filled fissures.

The relative enhancement grades are “None,” “Insignificant” to “Minor (F1),” “Moderate (F2),” and “Significant.”

Note that some labs use the term “Insignificant” for the following situation: if removing the filler doesn’t decrease the stone’s quality, the filler doesn’t qualify as an “enhancement.” Therefore, a lab report need not mention it.

Other labs note any detected filler in an emerald, regardless of its insignificance.

Because quantification depends largely on visual judgment, you may encounter “minor” or even “significant” differences of opinion between laboratories. Nevertheless, quantification is really an attempt to let the customer know the clarity quality of the material itself. Higher-quality stones have fewer fissures, and thus will show lower levels of enhancement. However, the position of fissures also plays a critical role. For example, a single fissure nearly parallel to the table facet will appear extremely distracting, even if it’s the only fissure in the gem.

Clarity Enhanced vs Cavity Filled and Composite Emeralds

Beyond the “Significant” or F3 clarity enhanced grade are “Cavity Filled” with Minor (C1), Moderate (C2), and Significant (C3) filler. Then, there are also composite emeralds, where removal of the filler would result in the stone falling apart. Lead-glass filled rubies held together by the glass are considered composites and are classified as a manufactured product, just like composite emeralds would be.

Since the term “composite” traditionally referred to assembled stones, many gemologists prefer not to use this term for these emeralds. Perhaps “resin-filled emerald hybrid” would be the appropriate term.

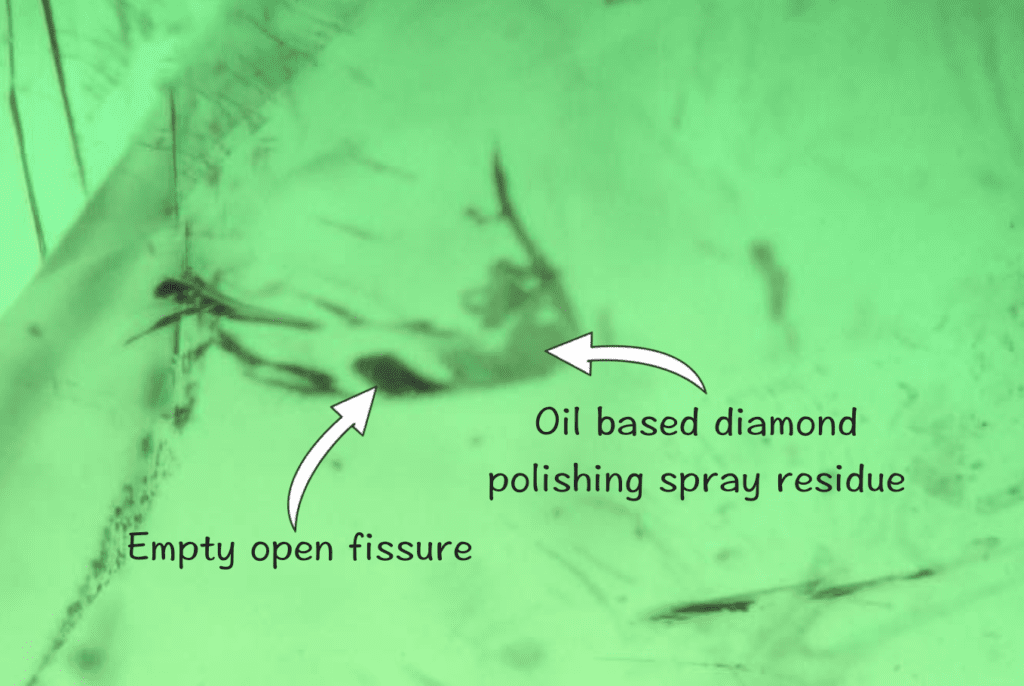

Residue After Polishing

Gem cutters typically apply diamond polishing powders in 50,000 and 100,000 grit to the polishing wheel with an oil-based spray. No matter how careful the cutter, a small amount of the oil will inevitably enter surface-reaching fissures.

While this isn’t intentional clarity enhancement, gemological lab reports routinely mention any detected incidental oil resides as “Insignificant” or “Minor” clarity enhancements. This happens even if the oil doesn’t actually improve the clarity.

Removing these incidental residues in order to receive a “No Enhancement” report can become an extremely difficult and time-consuming multi-step process. Further complicating the matter, emerald dealers would need to submit the emeralds for rechecks after each cleaning effort. If you’re shipping your emeralds to an overseas lab, this can get quite costly as well.

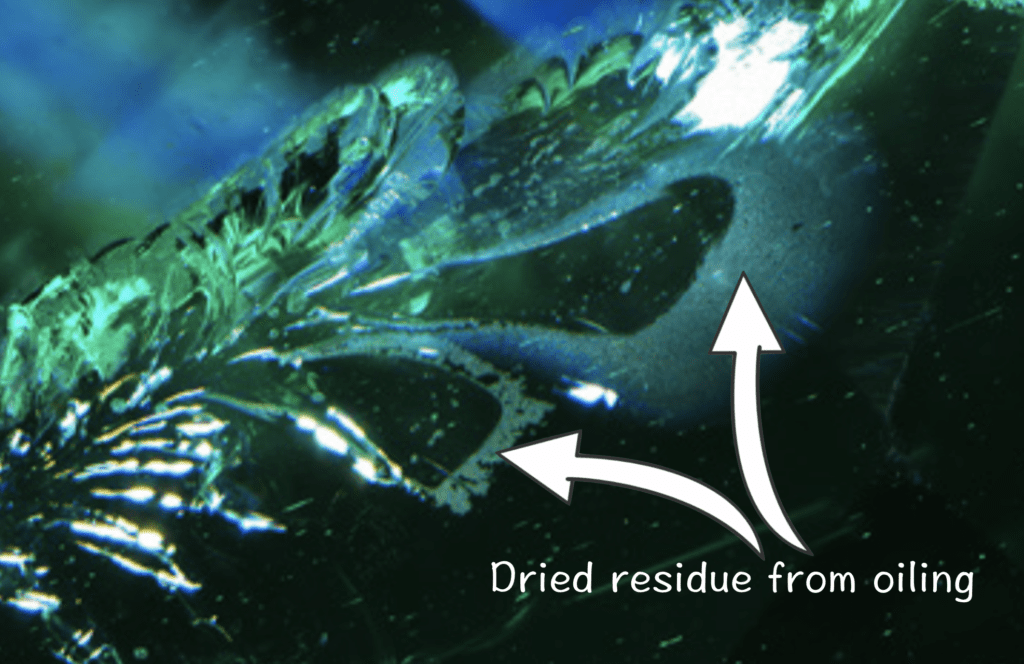

Residue After Cleaning

Natural oils (and to a much lesser extent synthetic resins) can dry out over time, leaving residues in emerald fissures. These residues typically appear as milky or cloudy spots or zones at the bottom of surface-reaching fissures. Some labs will note them, while others won’t, since the residues don’t actually enhance the emerald’s clarity.

Emerald Enhancements and Pricing

In Emerald Oiling: The Refining Process and Its Impact On Pricing (2016), George Smith, co-founder of International Emerald Exchange (IEEX), and K. Perez discuss the impact of clarity enhancement on emerald pricing:

Using a 3-carat stone of optimum colour and clarity as an example, with all things except level of treatment being equal, we can explore the effect this has on an emerald’s value. If a stone is graded as displaying “Minor” indications of clarity enhancement, prices could range from $12,000 to $18,000 USD per carat. If it belongs to the “Moderate” category, the value varies from $8,000 to $12,000 per carat. Finally, an emerald displaying “Significant” indications of treatment could be worth from nothing to $4,000 to $6,000 per carat. These prices are only a rough guide though, as there is a multitude of other factors that affect pricing.

Pricing for Unenhanced Emeralds

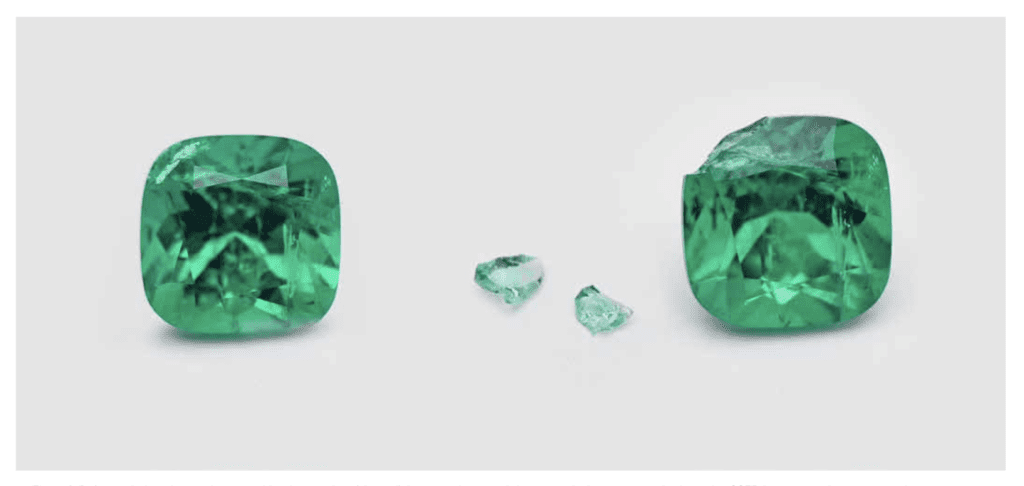

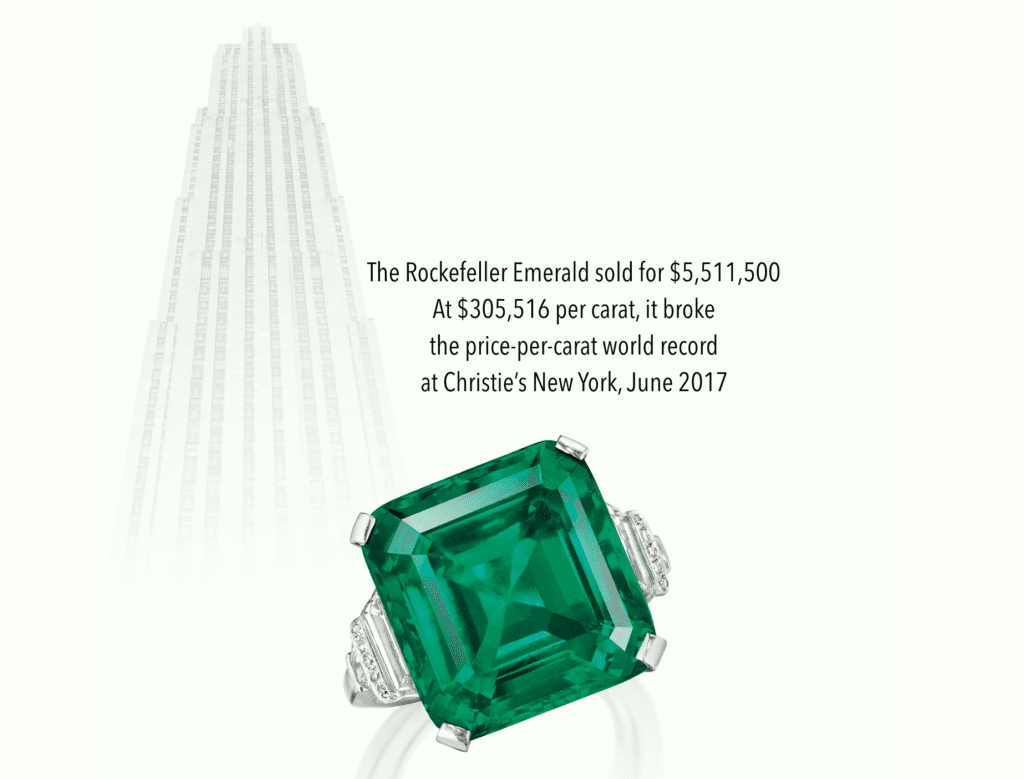

Compare those rough guidelines with the prices for these spectacular, unenhanced emeralds.

In May 2017 at the Joseph DuMouchelle auction in New York, a 3.30-ct natural Colombian emerald with no clarity enhancement sold for $343,750 USD or $104,166 per carat.

The following month, the Rockefeller Emerald was purchased for $5,511,500 USD at Christie’s New York. At $305,516 per carat, it broke the price-per-carat world record. The American Gemological Laboratory (AGL) described the Rockefeller Emerald as “exceptional” and possessing an “unusual combination of size, provenance, absence of treatment and quality factors that contribute favourably to its rarity and desirability.”

Conclusion

Protecting the consumer should be of paramount concern to everyone in the gem and jewelry trade. After all, it’s ultimately the consumer who puts food on our tables.

In the Guides for the Jewelry, Precious Metals, and Pewter Industries (Section ruling 23.22), the United States Federal Trade Commission (FTC) states:

It is unfair or deceptive to fail to disclose that a gemstone has been treated if:

(a) the treatment is not permanent. The seller should disclose that the gemstone has been treated and that the treatment is or may not be permanent;

(b) the treatment creates special care requirements for the gemstone. The seller should disclose that the gemstone has been treated and has special care requirements to the purchaser;

(c) the treatment has a significant effect on the stone’s value. The seller should disclose that the gemstone has been treated.

Consumer Advice

- AVOID hot and/or soapy water, ultrasonic cleaners, solvents such as acetone (nail polish remover), and alcohol.

- Buy only from reputable jewelers.

- Request an independent gemological laboratory report stating the clarity enhancement level of the emerald.

Trade Advice

- AVOID cleaning emeralds with off-the-shelf acetone-based nail polish remover, as the vast majority contain a small amount of lanolin.

- After soaking an emerald in acetone, oils and/or resins will dissolve. This will then necessitate discarding the acetone, flushing out the container, and refilling it with pure acetone. This process typically requires several cycles in order to thoroughly clean an emerald.

- Occasionally, removing all fillers will require strong acids. Don’t attempt this without guidance from someone experienced in the procedure. Never attempt this without proper protective equipment, clothing, and ventilation.

Gemological Laboratory Disclosure Notes for Emerald Enhancements

AIGS (Asian Institute of Gemological Sciences)

- None, Minor, Moderate, Significant.

- Filler identified upon request.

- Website: https://www.aigsthailand.com

AGL (American Gemological Laboratories)

- None, Insignificant, Minor, Moderate, Significant.

- Identified as Traditional (oils), Modern (resins), or both.

- Website: http://aglgemlab.com

Bellerophon GemLab

- None (Cannot be enhanced), No oil, Insignificant, Minor, Standard, Significant.

- Addition of * denotes resin. (For example, “Minor*” means “minor resin”).

- Website: https://www.gemlabanalysis.com

CDTEC (Center of Technological Development of the Colombian Emerald)

- None, Insignificant, Minor (F1), Moderate (F2), Significant (F3).

- Emerald without enhancement but residues which don’t improve the clarity: None.

- Comments: Contains residues from the cutting process. Filler on request: Oil (If 100% cedarwood oil: Cedarwood Oil), Wax, Artificial Liquid Resin, Artificial Hardened Resin, or a mix of oil and resin.

- Website: http://www.gemlabcdtec.com/home/en

DANAT (Bahrain Institute for Pearls and Gemstones)

- None, Minor, Moderate, Significant.

- Filler identified on request.

- Website: https://www.danat.bh

GIA (Gemological Institute of America)

- None (no fissures present), No indications of clarity enhancement (no or insignificant clarity enhancement), F1 (Minor), F2 (Moderate), F3 (Significant).

- Filler not identified.

- Website: https://www.gia.edu

GIT (The Gem and Jewelry Institute of Thailand)

- None, Minor, Moderate, Significant.

- Oil, resin, or both noted.

- Website: https://www.git.or.th/index_en.html

GRS (Gem Research Swisslab)

- None, Insignificant, Minor, Minor to Moderate, Moderate, Significant.

- Only when the treatment is graded as “moderate” or “significant” will the presence of resin be explicitly mentioned.

- Website: http://gemresearch.ch

GTL (Gem Testing Laboratory, Jaipur)

- None, Minor, Moderate, Significant.

- Oil, resin, or both.

- Website: http://www.gtljaipur.info

GTTL

- None, Minor, Moderate, Significant.

- Filler identified on request.

- Website: http://www.ggtl-lab.org

Gübelin Gem Lab

- None, Insignificant, Minor, Moderate, Significant.

- Traditional (oil-type), modern (resin-type), or both.

- Website: https://www.gubelin.com/cms/en/gemmology/unique-expertise/gubelin-gem-lab/

Guild GemLab

- None, Insignificant, Minor, Minor to Moderate, Moderate, Significant.

- Filler not identified.

- Website: http://www.guildgemlab.com/index.php/index/index.html

ICA GemLab (International Colored Gemstone Association)

- No indication of clarity enhancement, Insignificant, Minor, Moderate, Significant.

- Filler identified upon request.

- Website: https://www.icagemlab.com/en/home/

Lotus Gemology

- None, Minor, Moderate, Significant.

- Filler not identified.

- Website: https://lotusgemology.com

NGTC (National Gemstone Testing Center)

- N – none, IF – insignificant, F1 – minor, F2 – moderate, F3 – significant.

- Filler not identified.

- Website: http://www.ngtc.com.cn/index.php?m=Page&a=index&id=69&l=en

SSEF (Swiss Foundation for the Research of Gemstones)

- Emeralds with no fissures (very rare): as there are no fissures at the time of testing, these emeralds cannot and are not clarity enhanced by a fissure filler at the time of testing. In such a case, we will state on our report: no indications of clarity modification at the time of testing.

- Emeralds containing fissures, but without any clarity modification by a fissure filler are described as follows: no indications of clarity modification in fissures at the time of testing. This is to express that this emerald contains fissures, which should be eye-visible even to an untrained observer. Any such emerald may be refilled at any time after we have issued the report We therefore strongly urge our clients to have such emeralds rechecked by SSEF before buying the gemstone, especially if the report is not a very recent one and if the emerald looks very clean without any visible fissures.

- Emeralds which do contain fissures containing a filler substance for clarity modification are described as follows: indications of clarity modification. Minor (or moderate, significant) amount of oil (or artificial resin, etc) in fissures at the time of testing.

- Website: https://www.ssef.ch

Stone Group Laboratories

- No evidence of Clarity Enhancement, Minor Clarity Enhancement, Clarity Enhanced.

- No mention of type unless requested by client.

- Website: http://stonegrouplabs.com

Acknowledgements

I would like to express special thanks for contributions from the following friends and colleagues, without which this article would not have been possible: Richard W. Hughes, Martial Curti, Gabriel Angarita, Darwin Fortaleché, and Jean Claude Michelou.

References and Further Reading on Emerald Enhancements

Aeppel, T. (2007) How One Man Riled The Emerald Trade (Accessed 29-09-2019)

Christie’s (2019) Collecting guide: Emeralds (Accessed 29-09-2019)

DuMouchelle, J. (2017) Joseph DuMouchelle achieves more than $100,000 per carat for an Emerald at May 24 Jewels & Timepieces Auction (Accessed 29-09-2019)

EmeraldStone, Enhancements or “Treatments” (Accessed 29-09-2019)

Hänni, H.A. (1993) Filled emeralds: please face reality (Accessed 29-09-2019)

Hänni, H.A. (1993) Why epoxy-filled emeralds must be accepted (Accessed 29-09-2019)

Hänni, H.A. (1996) How to identify fillings in emeralds using Raman spectroscopy (Accessed 29-09-2019)

Hänni, H.A. (1998) Fracture Filling In Emeralds And Its Detection With Laboratory Methods (Accessed 29-09-2019)

Hughes, R.W, Zajicek, R. (1997) Catfights: Enhancement codes & trade wars (Accessed 29-09-2019)

Hughes, R. W. (2000) The Digital Devil: Don’t Forget to Flush (Accessed 29-09-2019)

Hughes, R.W. (2013) Cloak and Dagger: the politics of Opticon (Accessed 29-09-2019)

Hughes, R.W. et al. (2018) FTIR in Gem Testing • FTIR Intrigue • Lotus Gemology (Accessed 29-09-2019)

Johnson, M.L. (2007) Durability Testing of Filled Emeralds (Accessed 29-09-2019)

Krzemnicki, Dr. M.S. (2018) Emeralds and the Saga of Cleaning and Filling Fissures (Accessed 29-09-2019)

LMHC (2012) Information Sheet #5 – Standardised Gemmological Report Wording – Emerald (Accessed 29-09-2019)

McClure, S.F. et al. (1999) Classifying Emerald Clarity Enhancement at the GIA Gem Trade Laboratory (Accessed 29-09-2019)

Panjikar, J. Emerald treatments and its disclosure (Accessed 29-09-2019)

Perez, K. (2016) Emerald Oiling: The Refining Process and Its Impact On Pricing. (Accessed 29-09-2019)

Ringsrud, R. (1983) The Oil Treatment of Emeralds in Bogota, Colombia (Accessed 29-09-2019)

Roskin, G. (2007) Emerald Crack-Up (Accessed 29-09-2019)

Roskin, G. (2002) C.E.L. Renames Gematrat Emerald Filler (Accessed 29-09-2019)

Scarratt, K. (2015) Beautifying Emeralds – Perennial Debate… (Accessed 04-05-2020)

Weldon, R. (1997) Special Report: Colored Gems Emeralds (Accessed 29-09-2019)